Custom Moulding

Plasmo’s expert staff can work with you to develop custom-made plastic parts and products for packaging and non-packaging applications. We can develop items from concept to finished product, using either injection moulding or blow moulding techniques.

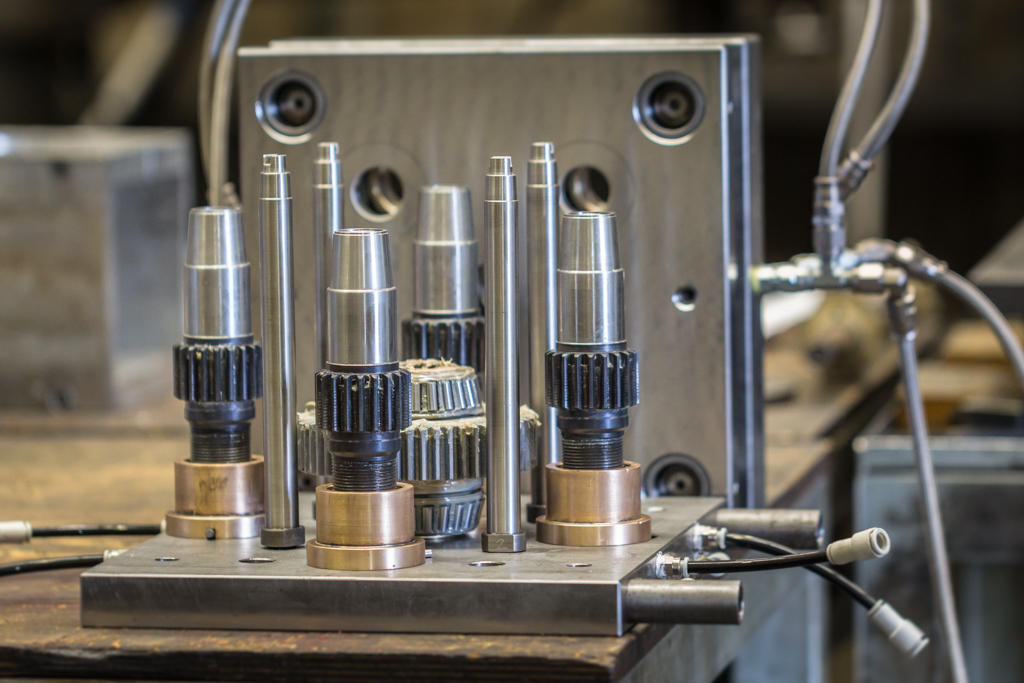

Our expertise over a number of disciplines such as design, toolmaking, polymer knowledge and moulding, enables us to make the development of products an enjoyable and trouble free process.

We use the latest technology including high-end 3D design software, computer controlled tool-room equipment and computer controlled moulding machines.

Advice and Quotations

We can advise you about design and production options and provide you with a quotation that is tailored to your budget. Confidentiality and exclusivity are assured.

We can help determine the cheapest and best moulding solution for your product, whether it requires a simple single cavity mould or a complex multi-cavity mould using hot runners, moving cores and unscrewing mechanisms.

We can use a staged approach, initially moulding trial samples and then making any modifications, if required, to improve the functionality of the product. This approach is relatively easy and cheap as all the data is stored in 3D.

For an initial consultation about your custom product requirements please contact us .