Product and Mould Design

During the design phase our designers, engineers and other specialists will work in collaboration with you (and other specialists you may nominate) to develop CAD designs that meet your product brief, accurately and cost effectively, perhaps with some additional innovative ideas. Using the latest design technology, we can assist and advise you on new concept development, plastic part design, prototyping and the final manufacture, whether for blow moulded, or injection moulded plastic products.

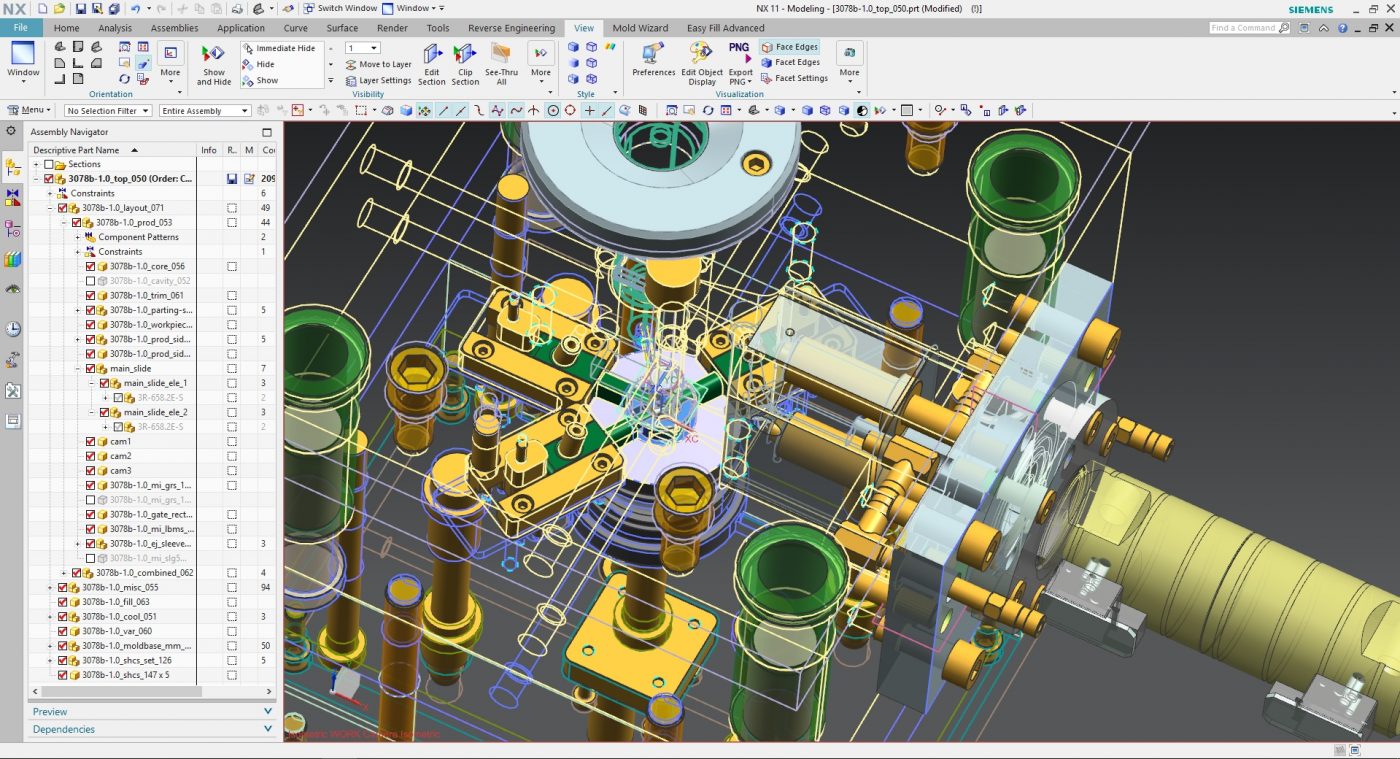

Mould design is particularly crucial in the product development process, being one of the most expensive investments in the overall process. For this reason, all tooling is CAD modelled prior to manufacture, enabling fast and efficient product design changes or mould changes as well as modifications and maintenance if required.

Physical prototypes and CNC machined models of items can be made prior to making the moulds if required. These allow you to evaluate the form, fit and function of your components, and identify if modifications are necessary to avoid any costly design errors prior to mould making. Finally, to ensure you are satisfied that your end product fits your brief, mould trialling is conducted prior to final manufacture.

Core Capabilities:-

- In-house design facilities

- In-house tool room

- High end NX CAD/CAM Siemens software

- 3 and 5-axis DMG CNC milling machines

- Plastics and polymer experience

- End product manufacture

Let our professional team help you to achieve the results you seek. Contact us to discuss a comprehensive solution to your plastic product design and toolmaking needs. Confidentiality is guaranteed.