Toolmaking

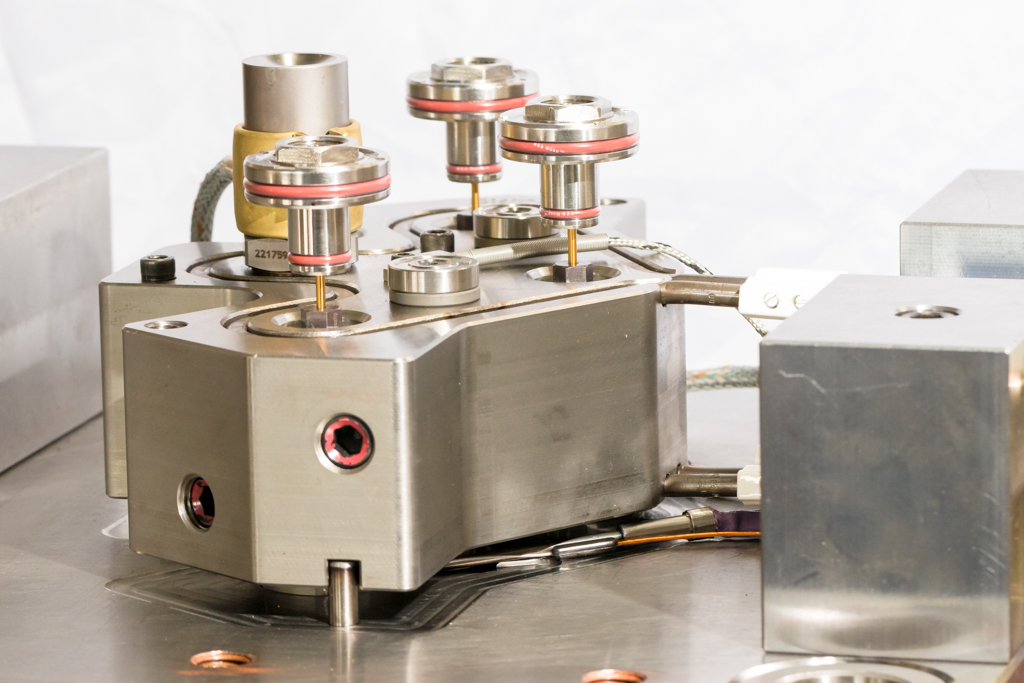

Plasmo has earned a reputation for giving value for money for the design and manufacture of good quality moulds, whether they are small and simple or complex and sophisticated.

We design and manufacture all moulds to exacting tolerances with durability and production efficiency in mind. Mould trialling is conducted prior to production so that the customer can be sure the end product fits all required specifications.

Some of the key factors for this success are:

- All moulds are made and maintained within Plasmo’s sophisticated in-house tool room.

- Plasmo employs only highly skilled and experienced toolmakers.

- Our toolmakers become involved in the critical early stages of product development and mould design, to ensure that the products can be made efficiently and at the lowest cost.

- The latest high-end CAD/CAM software is used for both design and manufacture.

- High quality CNC machines and the capability to run 24 hours unmanned, enable us to make moulds to greater precision in less time, resulting in better tools at a cheaper price.

- Moulds are designed and made to match the required output with multi-cavities, fast moulding cycles, low maintenance and longevity in mind. This ensures value for money and the cheapest unit price for your plastic parts in the long term.

Core Capabilities:-

- 3 and 5-axis DMG CNC milling machines

- Charmilles EDM machine

- High end NX CAD/CAM Siemens software

- Plastics and polymer experience

- End product manufacture